AN fittings or “Army-Navy fittings” are fluid system fittings that connect different components. They were originally designed for military aircraft during World War II but are now used in automotive, racing, aerospace, and other industries because they are tough and accurate parts. Be it a custom car overhaul or changing a hose in a plane, AN fittings will be involved in getting the leak-free operation of the system.

What Are AN Fittings?

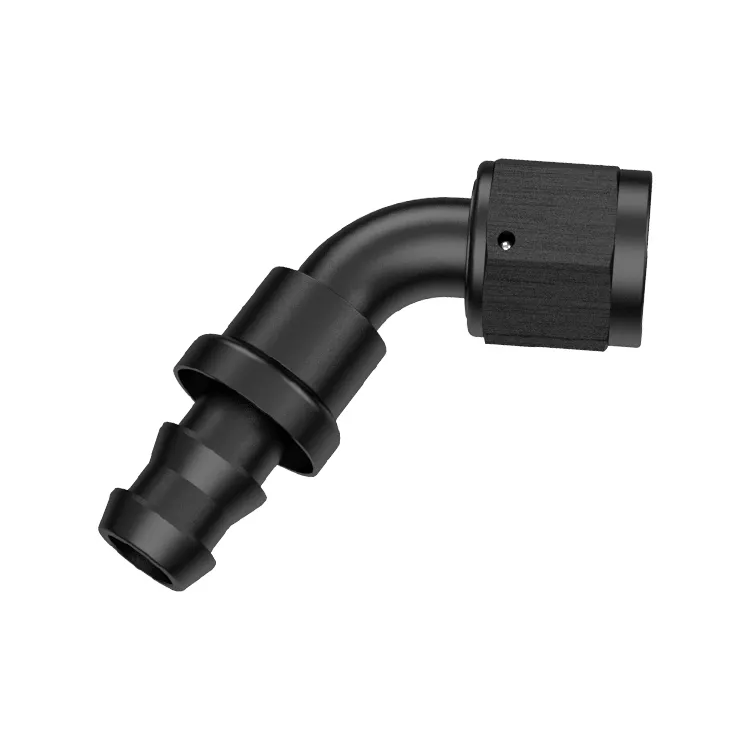

You should use flexible hoses and rigid tubing with AN fittings because the sealing capabilities of these fittings are so strong they will withstand high-pressure. The technicians make these parts out of aluminum, brass, or stainless steel to make them corrosion-resistant and tough. These fittings incorporate a unique thread pattern which prevents them from coming loose when vibration is present. Another beneficial feature of AN fittings is that they are reusable, making them cheap in applications that undergo frequent repairs.

There are many different sizes of AN fittings as the number before the AN (AN-6, AN-8 etc.) denotes the size of the fitting in terms of hosing/tubing. This sizing system is made possible as it is based on the inner diameter of the hose, and each number corresponds to sixteen. For example, AN-6 comes with a fitting that is best suited for a 6/16 inch (3/8 inch) internal diameter hose. This uniformity in sizes makes sure that any different parts can be combined easily, creating the possibility of multiple uses.

Uses of AN fittings

Authorities in motorsport have been witness to the growing need for AN fittings as these high-performance fluid systems are essential. Fuel hoses, oil hoses, or brake hoses are ideal for AN fittings thanks to the high reliability and pressure tolerance they offer. Especially in racing, which demands the utmost precision and durability of components where fluid transfer systems must be intact under extreme conditions, AN fixtures deliver the goods.

Interestingly, AN fittings are not restricted to racing as they are commonly used in aviation, marine and industrial fluid systems where vibration, heat and pressure resistance are needed. Moreover, their leak-proof design is important in systems in which fluid integrity is critical: hydraulic systems and coolant lines are two examples.

Why AN Fittings?

AN fittings include several notable advantages over the conventional hose and pipe connectors. Their strength, physical construction and ability to withstand high pressures makes them a good fit in extreme working conditions. Furthermore, the anodized finishes offered on many AN fittings enhance their corrosion resistance, which is a critical factor in abusive situations such as racing or outdoor applications.

The other major advantage is the convenience of working with AN fittings. A bite-type seal or an O-ring is commonly used to AN fittings, enabling efficient connections that can be made and broken easily. This is to remove the leakage problem in unions. The precise threads also protect the fittings from loosening and slippage as time moves on thereby making these fittings long-lasting.

In conclusion, the majority of high torque around fluid systems in racing vehicles and such used in aircrafts make use of AN fittings as one of the major components. Their strength, convenience of usage and capabilities to withstand high pressure extend the applicability of these fittings across various industries where accuracy and reliability are paramount. Both engineers and amateurs alike will be able in rendering the efficiency of their fluid systems whether in the field or in the air with respect to the fittings’ dimensions, materials, and applications.

Hot News

Hot News2025-06-11

2025-06-12

2025-06-13